Berkeley Darfur Stove Project Well Underway!

After several stove design revisions and a good bit of what we hope is field appropriate stove testing, Brian (the project engineer-on-the-ground) has arrived in Khartoum – let the next phase of the project begin! For those of you who are catching up, LBNL researchers and UCB students have been working on a new wood/biomass burning cookstove for IDP (internally displaced people – a nice name for refugees who still live within their own country) in Darfur, Sudan. I won’t get into the political or humanitarian aspects of the problem here (see earlier posts and the links within them), suffice to say that 2 million people live in mass camps in western Sudan, supplied with food aid by international agencies, but they are not provided with fuel to cook it. The women are forced to hike ever farther away from the camps to find firewood in an increasingly

After several stove design revisions and a good bit of what we hope is field appropriate stove testing, Brian (the project engineer-on-the-ground) has arrived in Khartoum – let the next phase of the project begin! For those of you who are catching up, LBNL researchers and UCB students have been working on a new wood/biomass burning cookstove for IDP (internally displaced people – a nice name for refugees who still live within their own country) in Darfur, Sudan. I won’t get into the political or humanitarian aspects of the problem here (see earlier posts and the links within them), suffice to say that 2 million people live in mass camps in western Sudan, supplied with food aid by international agencies, but they are not provided with fuel to cook it. The women are forced to hike ever farther away from the camps to find firewood in an increasingly  denuded landscape – at serious risk to their security. A single round trip can take 7 hours and several trips a week are necessary. Presently they use mostly simple stoves and “3 stone fires”, which are not inherently fuel efficient – improved stoves which are suited for their environment and cooking situation will not restore their homes, but it would reduce their risk (by reducing the number of trips they need to make) and buy some time until the world can figure out how to get fuel trucked in, so that people are safer and the environment can recover from the deforestation caused by so many people in so small a place.

denuded landscape – at serious risk to their security. A single round trip can take 7 hours and several trips a week are necessary. Presently they use mostly simple stoves and “3 stone fires”, which are not inherently fuel efficient – improved stoves which are suited for their environment and cooking situation will not restore their homes, but it would reduce their risk (by reducing the number of trips they need to make) and buy some time until the world can figure out how to get fuel trucked in, so that people are safer and the environment can recover from the deforestation caused by so many people in so small a place. This research group developed a stove which addresses local needs – it fits traditional pots sizes/shapes, it can be staked to the ground to secure it during their vigorous stirring, the pots are shielded from the both of their wind to improve efficiency, it can be manufactured locally by craftsman metalworkers, and it saves sufficient fuel day-after-day so that the purchase price is affordable. To find ways to make it more manufacturable locally, they contacted Engineers Without Borders – engineering skills and experience were needed to make the implementation on a mass scale more likely. Western engineering methods and tools were then used to adjust the design, but the local materials, skills, tools, and cooking methods were always kept in mind – even the stove testing used actual pots (and onions stir fried in oil – to simulate their local mulah dish) to monitor the efficiency as different designs were evaluated.

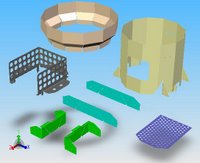

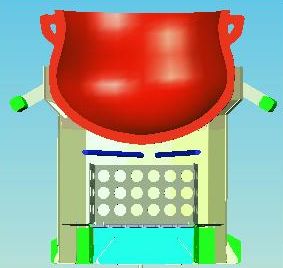

This research group developed a stove which addresses local needs – it fits traditional pots sizes/shapes, it can be staked to the ground to secure it during their vigorous stirring, the pots are shielded from the both of their wind to improve efficiency, it can be manufactured locally by craftsman metalworkers, and it saves sufficient fuel day-after-day so that the purchase price is affordable. To find ways to make it more manufacturable locally, they contacted Engineers Without Borders – engineering skills and experience were needed to make the implementation on a mass scale more likely. Western engineering methods and tools were then used to adjust the design, but the local materials, skills, tools, and cooking methods were always kept in mind – even the stove testing used actual pots (and onions stir fried in oil – to simulate their local mulah dish) to monitor the efficiency as different designs were evaluated. Back to the present. Brian will stay in Khartoum (the far away capital, but the only city that has some of the metal working tools needed to see how stoves can be initially built) for 3 months, assessing the situation, developing local contacts for metal supplies and tools, establishing local efficiency testing for quality control of stoves, and diving into the local culture. He left the U.S. with the best information that we could supply him with – stove plans, possible methods of assembly, an assembled stove and several kinds of templates for teaching people how stoves should be made (so that usability and efficiency are not altered significantly), and the best stove testing methods that we know of. His computer contains SolidWorks software models of the

Back to the present. Brian will stay in Khartoum (the far away capital, but the only city that has some of the metal working tools needed to see how stoves can be initially built) for 3 months, assessing the situation, developing local contacts for metal supplies and tools, establishing local efficiency testing for quality control of stoves, and diving into the local culture. He left the U.S. with the best information that we could supply him with – stove plans, possible methods of assembly, an assembled stove and several kinds of templates for teaching people how stoves should be made (so that usability and efficiency are not altered significantly), and the best stove testing methods that we know of. His computer contains SolidWorks software models of the stove – one of the tools that EWB contributed – so that he can demonstrate how the stove parts are assembled, what they do, why they are necessary, and he can alter the design as needed. This won’t help him directly in machine shops there, but it is a powerful tool for talking about stove designs and illustrating our approach. But all of this only tries to anticipate what he will find in Khartoum (let alone Darfur!), where we expect that nothing is what we think it is, despite several fact finding trips there to see what the stove building possibilities and use situations are.

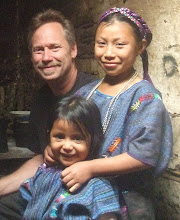

stove – one of the tools that EWB contributed – so that he can demonstrate how the stove parts are assembled, what they do, why they are necessary, and he can alter the design as needed. This won’t help him directly in machine shops there, but it is a powerful tool for talking about stove designs and illustrating our approach. But all of this only tries to anticipate what he will find in Khartoum (let alone Darfur!), where we expect that nothing is what we think it is, despite several fact finding trips there to see what the stove building possibilities and use situations are. Once he shakes of the jetlag and adjusts to the local accommodations and diet, he’ll explore the already identified metalworking shops, find more choices, see how local craftsmen make sheet metal products by hand, see if immediate modifications need to be made because of obvious local limitations (we hope not many – we tried to take many possibilities into consideration), and try and establish how prototype stoves might be made and how much they will cost to produce. Lots of flexibility and patience are expected to be necessary. The latest stove design left without any efficiency testing (it is hopefully just an incremental change to the previous tested design), but Brian has a stove testing lab with assistants there so he has some hands to help him. We tested in Berkeley (and Alameda – I am still trying to remove the soot stains) with simulated Sudan conditions, but how do they really cook there, and how will this change the testing procedure? What size pieces of wood do they use in the camps, can the stoves be elevated for ease of tending or must they be on the ground, and does the WBT adequately simulate local conditions (though it is expected that this will only be used for stove development – field cooking tests are the next phase of the project)? His charter is to start by developing the process for the first 50 prototypes stoves – we can only hope that he can start to understand real implementation in Darfur, where many other stove use questions need to be answered.

Once he shakes of the jetlag and adjusts to the local accommodations and diet, he’ll explore the already identified metalworking shops, find more choices, see how local craftsmen make sheet metal products by hand, see if immediate modifications need to be made because of obvious local limitations (we hope not many – we tried to take many possibilities into consideration), and try and establish how prototype stoves might be made and how much they will cost to produce. Lots of flexibility and patience are expected to be necessary. The latest stove design left without any efficiency testing (it is hopefully just an incremental change to the previous tested design), but Brian has a stove testing lab with assistants there so he has some hands to help him. We tested in Berkeley (and Alameda – I am still trying to remove the soot stains) with simulated Sudan conditions, but how do they really cook there, and how will this change the testing procedure? What size pieces of wood do they use in the camps, can the stoves be elevated for ease of tending or must they be on the ground, and does the WBT adequately simulate local conditions (though it is expected that this will only be used for stove development – field cooking tests are the next phase of the project)? His charter is to start by developing the process for the first 50 prototypes stoves – we can only hope that he can start to understand real implementation in Darfur, where many other stove use questions need to be answered.How do they feed their fires, how do they view any process of improving the efficiency of precious wood utilization, can their cooking processes be slightly modified just to save wood, will they share stoves between families, what challenges do they face in their lives that may hinder efficiency improvements (Dean Still’s the “sick child scenario” – real cooks cannot just focus on tending fires optimally), what further stove design changes will they ask for, and what do they value in stoves that we can emphasize so that efficiency improvements will not be lost over time.

It is my estimation that the stove design itself addresses some of the wood consumption problem, but just as important is how fires are tended – a program that just seeks to teach the best possible methods (no new stoves) would by itself have a tremendous impact on efficiency. What prevents IDP women from presently selecting the best present methods (copying the most efficient cooks), and disseminating these through the camps – to reduce fuel use on their own? This kind of cultural issue can only be answered by visiting, sitting, and learning. Too much to worry about for right now, especially with the present situation in the camps becoming more volatile, we can only start the process by making stoves available for the cultural evaluation phase – will people use them and will they indeed reduce fuel use? Once this is worked out, expanding manufacturing and working out the dissemination details will come next. I doubt that we will ever be done evaluating the impact of the whole effort (stove design and manufacture, plus effective implementation), and engineers can help with this as well – we are trained to collect data, evaluate it, then solve the problems identified by the analysis.

It is my estimation that the stove design itself addresses some of the wood consumption problem, but just as important is how fires are tended – a program that just seeks to teach the best possible methods (no new stoves) would by itself have a tremendous impact on efficiency. What prevents IDP women from presently selecting the best present methods (copying the most efficient cooks), and disseminating these through the camps – to reduce fuel use on their own? This kind of cultural issue can only be answered by visiting, sitting, and learning. Too much to worry about for right now, especially with the present situation in the camps becoming more volatile, we can only start the process by making stoves available for the cultural evaluation phase – will people use them and will they indeed reduce fuel use? Once this is worked out, expanding manufacturing and working out the dissemination details will come next. I doubt that we will ever be done evaluating the impact of the whole effort (stove design and manufacture, plus effective implementation), and engineers can help with this as well – we are trained to collect data, evaluate it, then solve the problems identified by the analysis.Next: Testing and Statistics for Stovers

0 Comments:

Post a Comment

<< Home